cGMP Standards: What They Mean for Your Medications and Health

When you take a pill, you expect it to work the way it should—no surprises, no contamination, no wrong dose. That’s not luck. It’s thanks to cGMP standards, current Good Manufacturing Practices that enforce strict quality control in pharmaceutical production. Also known as current Good Manufacturing Practices, these rules are the backbone of every approved medicine you buy at the pharmacy. Without them, a drug could be weak, tainted, or even dangerous. The FDA and global health agencies don’t just recommend cGMP—they require it. If a factory doesn’t follow these rules, their products get pulled. Period.

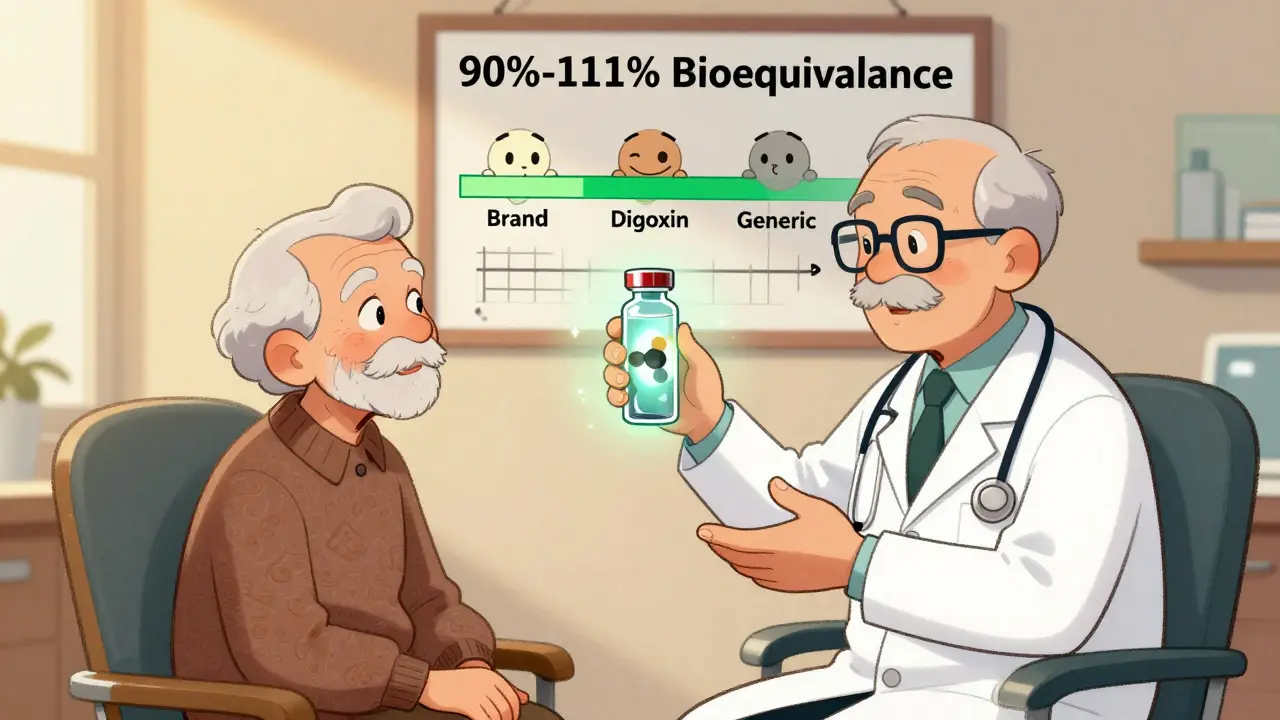

These standards cover everything: how raw ingredients are tested, how clean the machines are, how workers are trained, and even how records are kept. It’s not just about the final product. It’s about the whole process. For example, if a batch of insulin is made in a room where humidity isn’t controlled, it could clump up and become ineffective. cGMP stops that. It also ensures that generic drugs aren’t just cheap copies—they’re just as reliable as the brand-name versions. You might not see it, but cGMP is why your blood pressure pill from one brand works the same as another.

Related to this are pharmaceutical manufacturing, the end-to-end process of producing medications under regulated conditions, and FDA regulations, the legal framework that enforces safety and consistency in drug production. These aren’t abstract rules—they directly impact real people. A faulty batch of antibiotics could lead to treatment failure. A contaminated painkiller could cause organ damage. That’s why cGMP isn’t just paperwork. It’s a shield.

Look at the posts below. You’ll see articles on Combipres, Synthroid, Aristocort, and other medications. Each one of those drugs was made under cGMP. The same rules apply whether it’s a steroid cream, a thyroid pill, or a chemotherapy drug. These standards don’t care if the medicine is for high blood pressure or dry eyes—they protect you the same way every time.

You don’t need to be a scientist to understand why this matters. You just need to know that when you open a bottle, you’re trusting that someone else followed the rules. And with cGMP, those rules are strict, checked, and enforced. The system isn’t perfect—but without it, the risks would be far worse. What you’ll find here are real-world examples of how those rules play out in the medications you use every day. From how they’re made to why side effects happen, it all ties back to one thing: quality control you can count on.

How FDA Ensures Generic Drug Quality During Manufacturing

The FDA ensures generic drug quality through strict cGMP standards, unannounced inspections, and rigorous testing of every manufacturing step-not just the final product. Learn how the system keeps generics safe, effective, and affordable.