Every year, 22 million American workers are exposed to dangerous noise levels on the job. That’s not just a statistic-it’s 22 million people at risk of losing their hearing permanently, often without ever realizing it until it’s too late. Noise-induced hearing loss (NIHL) doesn’t happen overnight. It creeps in slowly, over months or years, masking itself as background hum or tired ears at the end of a shift. By the time workers notice the problem-struggling to hear conversations in noisy rooms, turning up the TV too loud-it’s usually permanent. The good news? This kind of hearing loss is almost entirely preventable. And the law says so.

What a Hearing Conservation Program Actually Is

A Hearing Conservation Program (HCP) isn’t just a policy on a wall or a yearly training video you half-watch. It’s a legally required system designed to stop noise from stealing your hearing. Under OSHA’s 29 CFR 1910.95 regulation, any workplace where employees are exposed to noise at or above an 8-hour average of 85 decibels (dBA) must have a full HCP in place. That’s the action level. It’s not the limit-it’s the trigger. Once you hit 85 dBA, the program kicks in. No exceptions. This isn’t about being extra careful. It’s about following federal law. And the consequences of skipping it are serious. OSHA issued over 1,800 citations for HCP violations in 2022 alone, with fines ranging from $15,625 to nearly $160,000 per violation. More than that, workplaces without proper programs see higher absenteeism and lower productivity. Workers with untreated hearing loss are more likely to miss work, make mistakes, or get injured because they can’t hear alarms, warnings, or instructions.The Five Core Components You Can’t Skip

A legal HCP has five non-negotiable parts. Missing even one means you’re not compliant-and you’re putting workers at risk.- Noise Monitoring: You can’t protect what you don’t measure. Employers must use calibrated sound level meters or noise dosimeters to identify areas where noise hits or exceeds 85 dBA. This isn’t a one-time check. Every time you change equipment, add machinery, or reconfigure a workspace, you need to retest. A new grinder, a louder fan, or even rearranging workstations can push noise levels over the limit.

- Audiometric Testing: This is the early warning system. Every employee exposed to 85 dBA or higher must get a baseline audiogram within six months of starting their exposure. The test must happen after at least 14 hours without workplace noise-no loud concerts, power tools, or even headphones the night before. After that, annual tests are mandatory. The frequencies tested? At least 500, 1000, 2000, and 3000 Hz. But by 2025, new rules are expected to require 4000 and 6000 Hz too, because that’s where early hearing loss shows up first.

- Hearing Protection: If noise is too loud, you give workers protection. But it’s not enough to hand out earplugs and call it done. Employers must provide a variety of options-earmuffs, foam plugs, custom-molded plugs-and train workers on how to use them correctly. A poorly fitted earplug can reduce protection by 90%. That’s why fit testing is becoming more common. And the protection must bring exposure down to at least 90 dBA. Not 95. Not 92. 90.

- Training: Annual training isn’t optional. It has to cover: how noise damages hearing, why hearing protectors matter, how to use them properly, and what the audiometric tests are for. Workers need to understand that this isn’t just a safety checkbox-it’s about keeping their ability to hear their kids, their favorite music, or even a conversation with a friend.

- Recordkeeping: You must keep noise exposure records for at least two years. Audiometric test results? Those must be kept for the entire time the employee works there. If they leave, you still have to store them. These records aren’t just for OSHA inspections-they’re your defense if a worker later claims their hearing loss was work-related.

What Happens When Hearing Loss Is Detected

The goal of annual audiograms isn’t just to track hearing over time-it’s to catch a Standard Threshold Shift (STS). An STS means a worker’s hearing has worsened by 10 dB or more, averaged across 2000, 3000, and 4000 Hz, compared to their baseline. When that happens, you have 30 days to act. First, you must notify the employee in writing within 21 days. No phone call. No email alone. A formal letter. Then, you must retrain them on hearing protection, refit their earplugs or earmuffs, and offer a higher-rated protector if needed. If the shift is significant or there’s reason to suspect a medical issue-like an ear infection or a tumor-you must refer them for a clinical audiological evaluation. This isn’t optional. It’s a medical red flag. And here’s something many employers miss: the baseline audiogram can be revised. If an STS is confirmed to be permanent and persistent, you can update the baseline to reflect the new level. That way, you’re not constantly flagging the same shift year after year. But you can’t do this without a professional supervisor of audiometry signing off.Why Most Programs Fail

OSHA’s data shows that 62% of violations are tied to audiometric testing problems. That’s the biggest failure point. Why? Because testing is messy. Workers don’t show up. They skip the 14-hour quiet period. The testing room isn’t soundproof. The audiometer isn’t calibrated. The results aren’t reviewed by a qualified professional. Another big issue? Training. 28% of violations come from inadequate training. Workers get handed earplugs like candy. They’re told, “Just wear these.” But they don’t know how to roll them properly, how to check the seal, or why it matters. A 2023 SHRM survey found that 68% of safety managers struggle with employee participation in testing. People don’t see the point. They think, “I can still hear fine.” Small businesses suffer the most. With fewer than 50 employees, 37% are non-compliant. Why? Cost. A full HCP runs $250-$400 per employee a year. Audiometric testing makes up nearly half of that. But here’s the truth: the cost of not doing it is higher. Lost productivity, workers’ compensation claims, OSHA fines, and lawsuits add up fast. Mobile audiometric units-used by 73% of compliant companies-cut employee downtime by 60%. That’s not an expense. It’s an investment.

What’s Changing in 2025

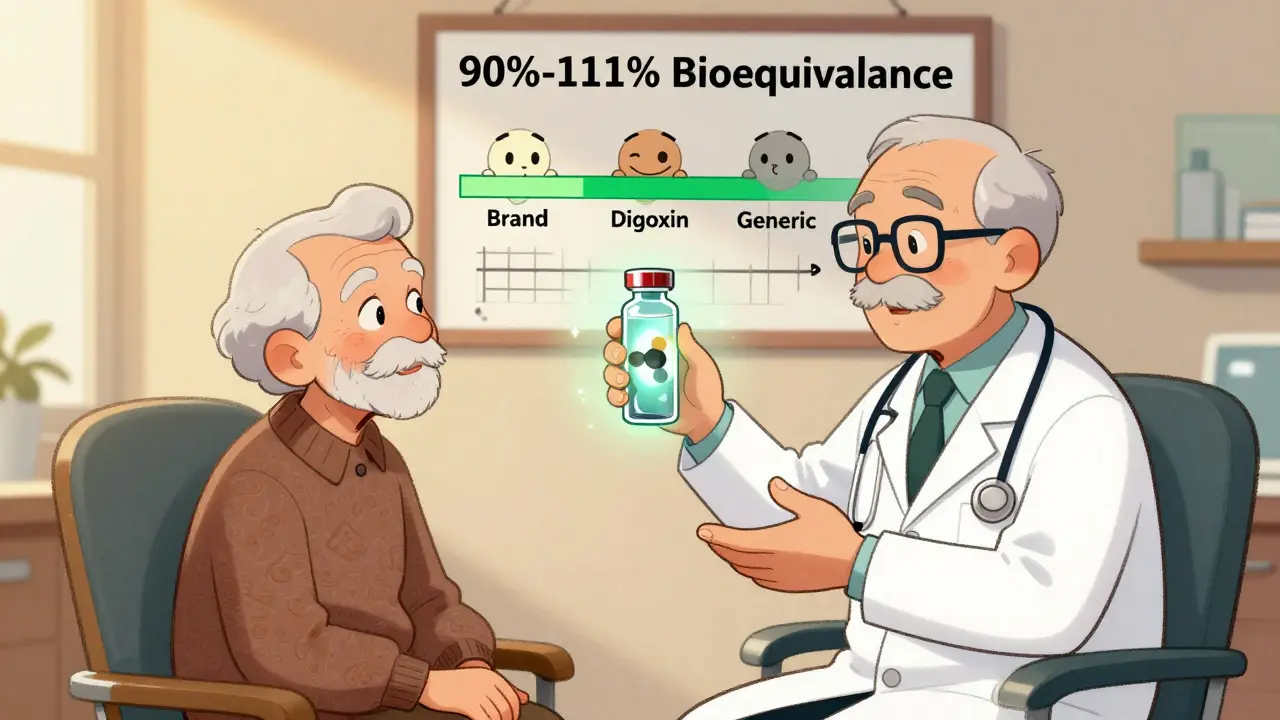

OSHA is updating the rules. The proposed changes, expected to be finalized in late 2024, will make HCPs stricter. Here’s what’s coming:- Audiometers must meet ANSI S3.6-2018 standards, not the outdated 1969 version.

- Testing must include 4000 Hz and 6000 Hz frequencies to catch early damage.

- Hearing protectors must be chosen based on actual noise levels-not just to bring exposure down to 90 dBA. If you’re exposed to 100 dBA, your protector must do more than just hit 90. It must be matched to the level.

What You Should Do Now

If you’re an employer:- Test your noise levels. Don’t guess. Use a calibrated meter.

- Identify everyone exposed to 85 dBA or higher.

- Get baseline audiograms for them-within six months, with 14 hours of quiet.

- Offer real choices in hearing protection. Let workers pick what works.

- Train them every year. Make it meaningful, not a PowerPoint slideshow.

- Keep records. Always.

- Act fast if an STS shows up. Don’t wait.

- Ask if your workplace has a Hearing Conservation Program.

- Make sure you’re getting your annual hearing test.

- Wear your protection correctly. If you can’t hear your own voice through the earplug, you’re doing it right.

- Report if your earplugs are uncomfortable or don’t fit. You deserve better.

- Don’t ignore ringing in your ears after a shift. That’s your body warning you.

What noise level triggers a Hearing Conservation Program?

A Hearing Conservation Program is required when employees are exposed to noise at or above an 8-hour time-weighted average of 85 decibels (dBA). This is called the action level under OSHA regulations. At this level, employers must begin noise monitoring, provide hearing protection, offer audiometric testing, train workers, and keep records.

How often do employees need hearing tests?

Employees exposed to 85 dBA or higher must get a baseline audiogram within six months of first exposure. After that, they must have an annual audiogram every year. The test must be conducted in a quiet room, and the employee must be free from workplace noise for at least 14 hours before the test.

What is a Standard Threshold Shift (STS)?

A Standard Threshold Shift (STS) is a measurable decline in hearing of 10 dB or more, averaged across 2000, 3000, and 4000 Hz, compared to the employee’s baseline audiogram. When an STS is detected, the employer must notify the employee in writing within 21 days, retrain them on hearing protection, refit their devices, and offer better protection if needed. A clinical evaluation may also be required.

Can I just give workers earplugs and call it a day?

No. Simply handing out earplugs does not meet OSHA requirements. Employers must provide a variety of hearing protection options, train workers on how to use them correctly, ensure proper fit, and verify that the protection reduces exposure to at least 90 dBA. Fit testing and ongoing training are required components of a legal program.

Are small businesses exempt from Hearing Conservation Programs?

No. OSHA regulations apply to all employers regardless of size. While small businesses (under 50 employees) often struggle with compliance due to cost and resources, they are not exempt. Non-compliance rates are higher among small businesses-37% compared to 18% in larger companies-but the legal requirement is the same. Mobile testing services and low-cost training tools can help smaller workplaces meet requirements affordably.

What happens if I don’t have a Hearing Conservation Program?

Without a program, you’re violating federal law. OSHA can issue citations with fines between $15,625 and $156,259 per violation, depending on severity and whether it’s willful or repeated. Beyond fines, you risk workers’ compensation claims, lawsuits, lost productivity, and higher injury rates. Workers who lose their hearing due to workplace noise may qualify for long-term disability benefits, which can cost employers far more than a compliant program.

Kevin Estrada

bro i work in a warehouse and they gave me these flimsy foam plugs that fall out in 5 minutes. like wtf is this. i can still hear the forklifts but my ears feel like they're full of cotton. no one cares until you start asking for your kids' names at family dinners.

Katey Korzenietz

I can't believe people still think earplugs are 'optional'. This isn't a suggestion, it's LAW. And if your company is skimping on audiograms? They're literally gambling with your hearing. 🚨

Chris Jahmil Ignacio

They say 85 dBA triggers the program but they never tell you most of these noise meters are calibrated wrong. I've seen the same machine read 87 one day and 82 the next because the tech didn't replace the battery. And now they want us to trust audiograms from a guy who's testing in a closet with a fan running? This whole system is a joke. OSHA doesn't even audit these properly. It's all paperwork theater.

Paul Corcoran

If you're reading this and you're an employer - stop treating hearing protection like a box to check. Talk to your team. Ask them what kind of protection actually works for them. Let them try different brands. Make training real. I used to work in a plant where they had a monthly 'hearing day' with snacks and one-on-one fit tests. People showed up. They cared. Because someone finally treated them like humans, not machines.

Stacy Natanielle

I'm a safety officer and I've seen too many STS cases ignored because 'the worker didn't show up for testing'. But what if they were working double shifts? What if they had no childcare? What if the testing was at 5am and they were told to 'just come in'? It's not laziness - it's systemic failure. 🤕

kelly mckeown

i've been wearing earplugs for 8 years and i never knew you had to wait 14 hours without noise before the test. i thought it was just 'don't go to concerts'. i feel so dumb. but also... why didn't anyone tell me this? my company just handed me a pamphlet and said 'wear these'.

Tom Costello

The 2025 updates are long overdue. ANSI S3.6-2018 isn't just a fancy number - it means the machines actually measure accurately. And testing at 6000 Hz? That's where early damage hides. I work in a factory where they used to skip that frequency because 'it's not required'. Now we're updating everything. It's not about compliance. It's about keeping people from becoming deaf before 40.

Justin Hampton

You think this is about hearing? Nah. It's about liability. Companies don't care if you go deaf. They care if you sue them. That's why they 'require' all this stuff - so they can say 'we gave them earplugs' when you take them to court. Don't be fooled. This isn't care. It's insurance.

Pooja Surnar

US companies are so lazy. In India we have mandatory hearing checks every 6 months in factories. No excuses. No 'we can't afford it'. You don't get to ignore safety because you're small. If you can't afford a mobile unit, you don't deserve to run a business. This is basic human dignity.

Sandridge Nelia

Just wanted to say - if you're a worker and your earplugs hurt or you can't get a good seal, speak up. I used to think it was me. Turned out the size was wrong. My company switched me to custom molds and now I can actually hear my coworkers without straining. It's not a complaint. It's a fix.

Mark Gallagher

This whole thing is a socialist plot. Why should American workers get free hearing tests while my taxes pay for it? If you can't hear, maybe you shouldn't be working in loud environments. Just get a quieter job. This isn't a right - it's a privilege earned by not being lazy.

Wendy Chiridza

I work in a small machine shop with 12 people and we just got our first mobile audiometric unit. It came for 2 days. We all got tested. No one missed work. The cost was $3000 total. We spent more on coffee last month. This isn't expensive. It's smart.

Pamela Mae Ibabao

Just had my annual test. They said I had a 12 dB shift. They sent me a letter. Then they gave me a new pair of earmuffs. Then they made me sit through a 45-minute training on how to put in earplugs. 😅 I'm 42. I've been doing this for 15 years. But hey - at least they tried. 🙏

Gerald Nauschnegg

I work in a plant where they do the testing in the break room. No soundproofing. No quiet. People are talking, coffee machines are on, the AC is roaring. And they call that an audiogram? That's not testing. That's a joke. And they wonder why 62% of violations are about testing? Because it's all fake.

Erik van Hees

You know what's worse than noise? People who think they're immune because they're 'used to it'. I've seen guys with 30 years on the job who still don't wear protection. 'I've been fine so far!' Yeah, until you can't hear your grandkids say 'I love you'. Then it's too late. Stop being a hero. Wear the damn plugs.