FDA manufacturing inspections: What they are and why they matter for your medications

When you take a pill, injection, or cream, you trust it’s safe and works as it should. That trust doesn’t come from luck—it comes from FDA manufacturing inspections, a system of on-site checks by the U.S. Food and Drug Administration to verify that drugmakers follow strict quality rules. Also known as pharmaceutical facility audits, these inspections are the backbone of drug safety in the United States. Without them, contaminated, weak, or even dangerous medicines could end up in your medicine cabinet.

These inspections aren’t random visits—they’re scheduled and unannounced checks on factories that make everything from insulin to blood pressure pills. The FDA looks at how clean the facility is, whether workers follow procedures, how raw materials are stored, and if equipment is properly maintained. If a plant fails, the FDA can block shipments, issue warning letters, or shut down production. In 2022, over 1,200 inspections were conducted in foreign countries alone, because nearly 40% of the medications Americans use are made overseas. That’s why the FDA doesn’t just trust paperwork—they send teams to walk the floors, check logs, and even test samples on-site.

Related to this are pharmaceutical quality, the consistent ability of a drug to meet its intended strength, purity, and performance, and FDA compliance, the legal requirement that manufacturers follow Current Good Manufacturing Practices (CGMP). These aren’t buzzwords—they’re what keep your Combipres from being mixed with the wrong filler, your Synthroid from losing potency, or your acetaminophen from being contaminated. The posts you’ll find here cover real-world impacts: how fluid retention from bad drug batches affects kidney patients, why steroid creams like Aristocort need sterile production lines, and how improper storage of medications like trazodone can turn a safe sleep aid into a risk.

You’ll also see how these inspections connect to things like diabetic kidney disease or Addison’s disease—because if your hydrocortisone isn’t made right, it won’t save your life. Or how a single error in a factory making capecitabine could put a cancer patient’s fertility at risk. These aren’t abstract policies. They’re the quiet, behind-the-scenes work that keeps your prescriptions reliable.

There’s no such thing as a perfect system, but FDA manufacturing inspections are the closest thing we have to a safety net. And when they work, you never even notice. That’s the point.

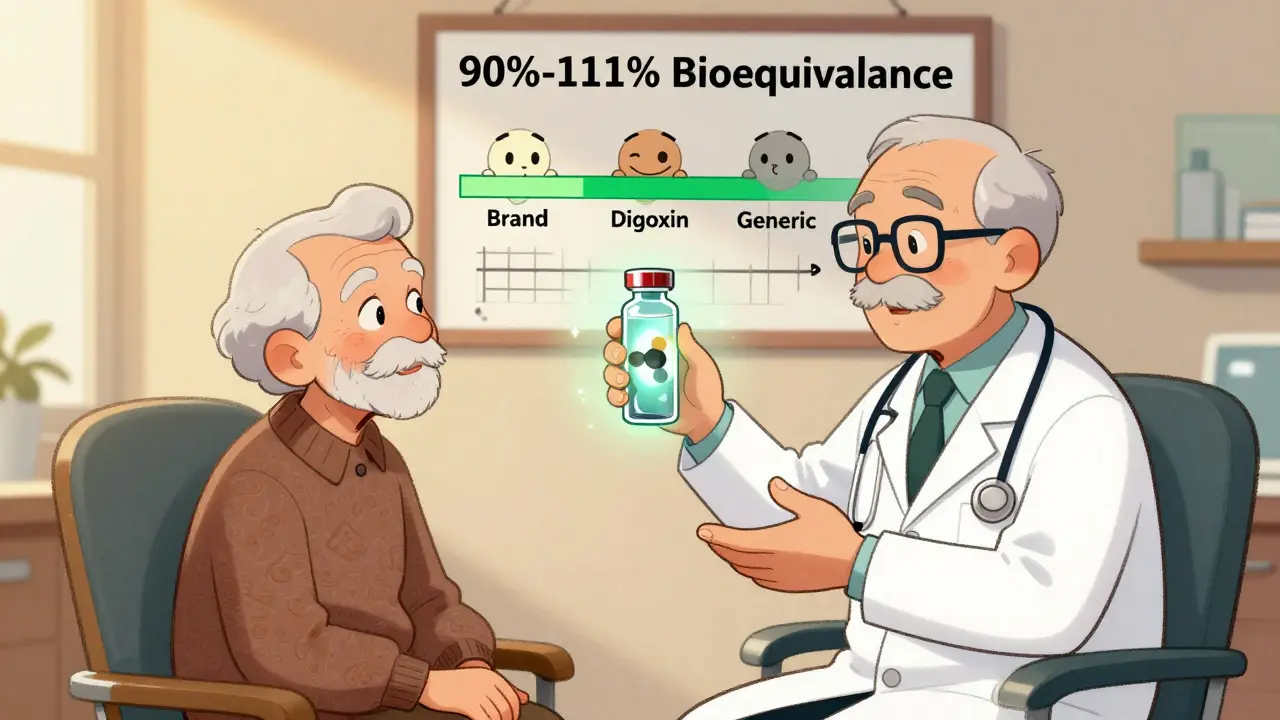

How FDA Ensures Generic Drug Quality During Manufacturing

The FDA ensures generic drug quality through strict cGMP standards, unannounced inspections, and rigorous testing of every manufacturing step-not just the final product. Learn how the system keeps generics safe, effective, and affordable.